About

In 2021, AspenTech introduced a new approach to managing industrial facilities called the “Self Optimizing Plant.” This approach leverages vast amounts of data and utilizes advanced technology to gain insights into production and make accurate predictions. Older plant managers who have a deep understanding the machinery are retiring and the new managers replacing them are more familiar with technology and expect simpler tools. With this change, valuable knowledge about dealing with unexpected problems is being lost.

To address this issue, AspenTech created a new system that helps plant managers and operators quickly identify and solve problems. This system combines data analysis and a user-friendly interface so that even managers without a lot of experience can easily understand what's going on and take action. The goal is to make plant management faster and more efficient.

Challenge

Filling the gap of knowledge created by a retiring generation

Many experienced workers who have a deep understanding of how different machines work together and their unique characteristics are retiring, causing a shortage of knowledge in complicated manufacturing processes.

Business Value

A streamlined workflow reduces overhead and improves operations

AspenTech can provide an AI-based solution to help plant managers and operators quickly identify potential issues and take action. This will reduce the time and effort needed from front-line workers.

User Value

More time for the important work

Plant managers and operators save time and can focus on other important tasks, instead of spending time diagnosing and fixing problems.

I like it. You can immediately see the asset, what is causing the issue,

you can also, if I look on the left. The Learn More is that going to

hyperlink you into the detail? Yeah.. That is a quick way to access

anything you want. Which is awesome, because you don’t always

want to see the same things.”

Keenesh

BluESP

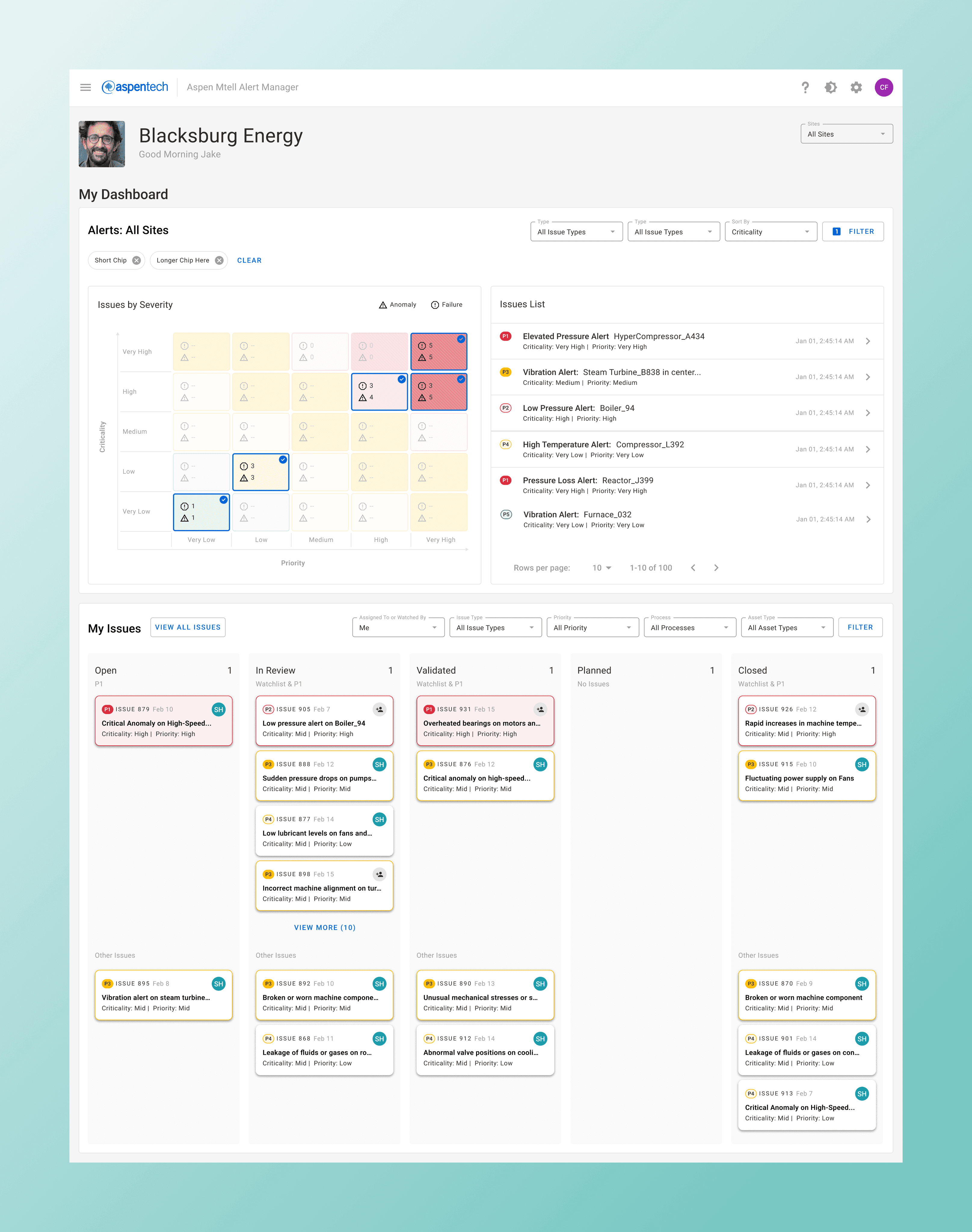

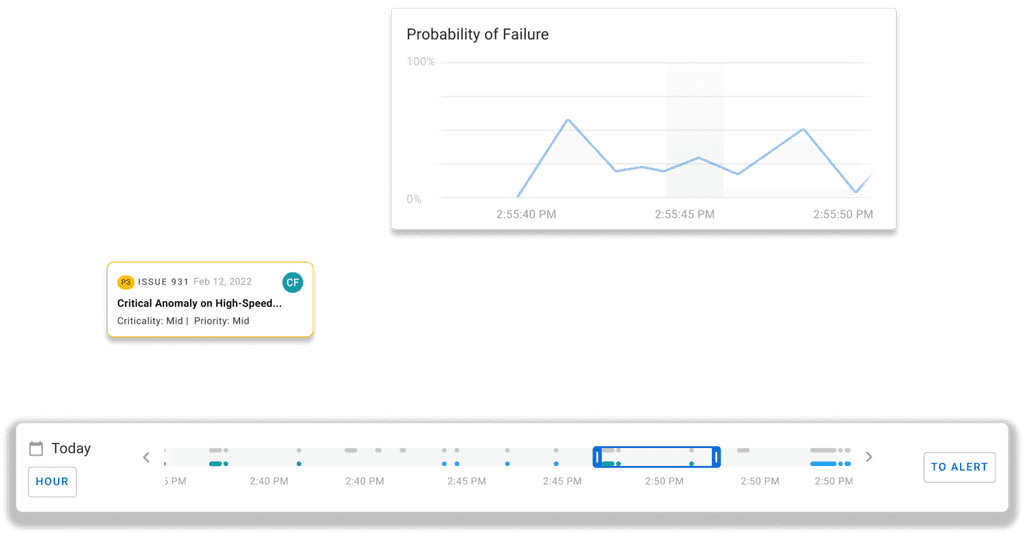

AI-powered asset monitoring for plant operations and management

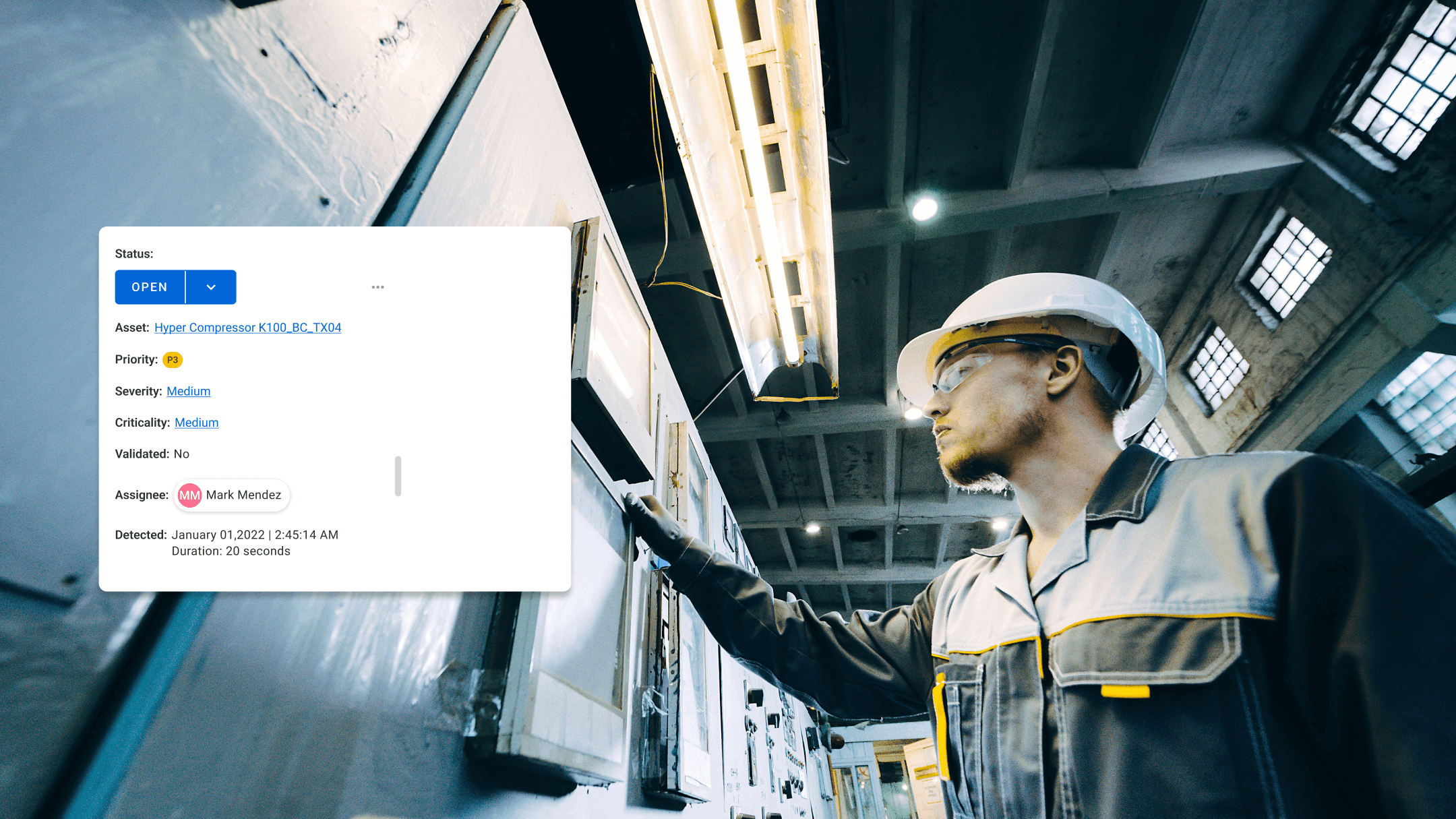

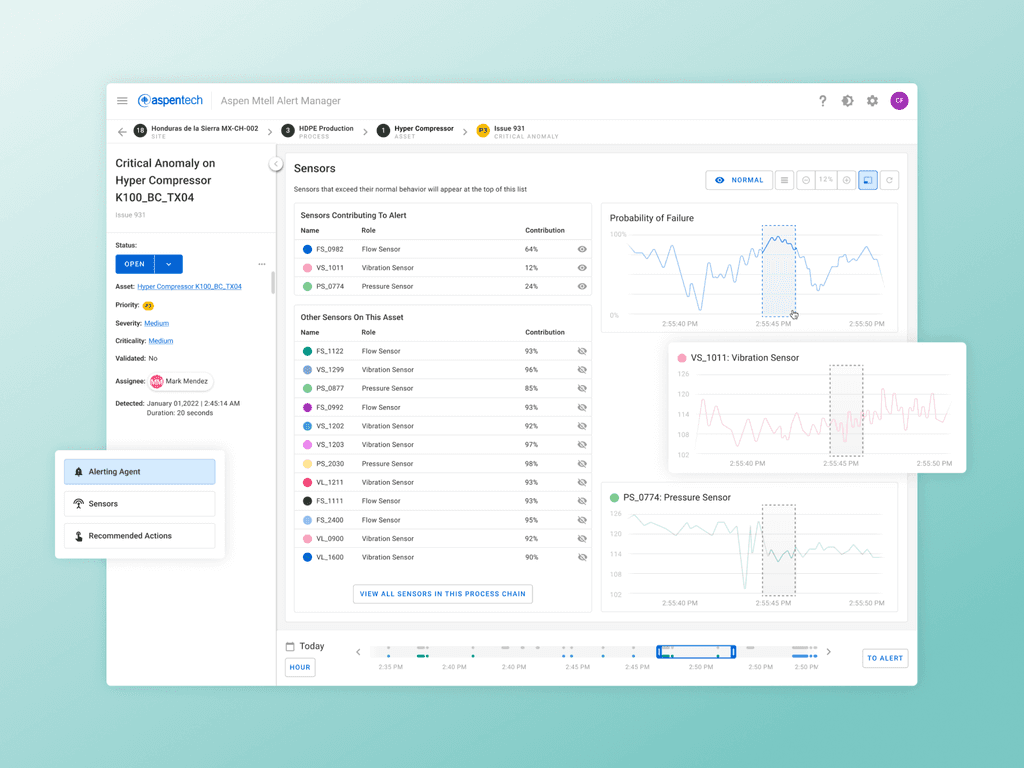

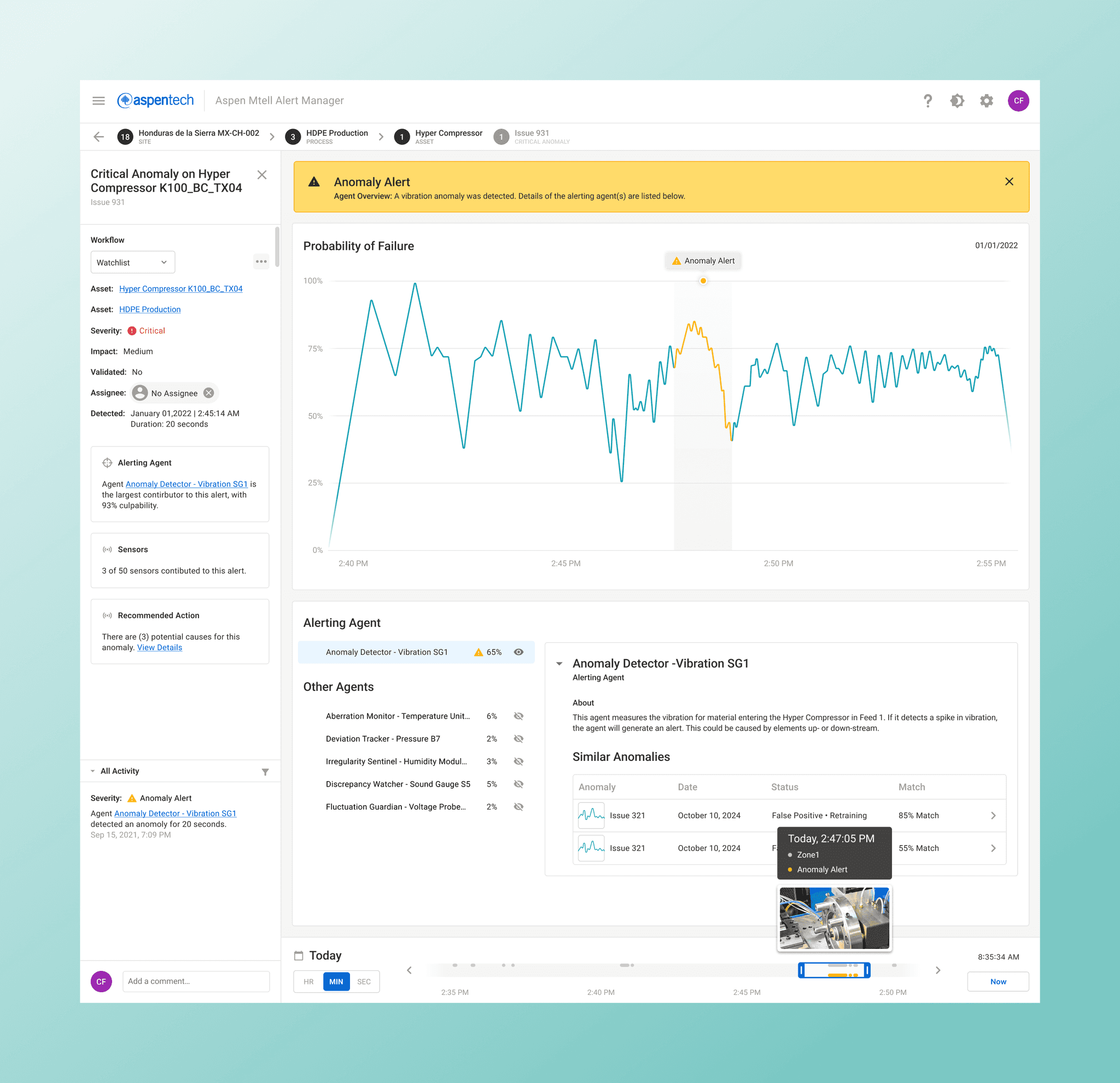

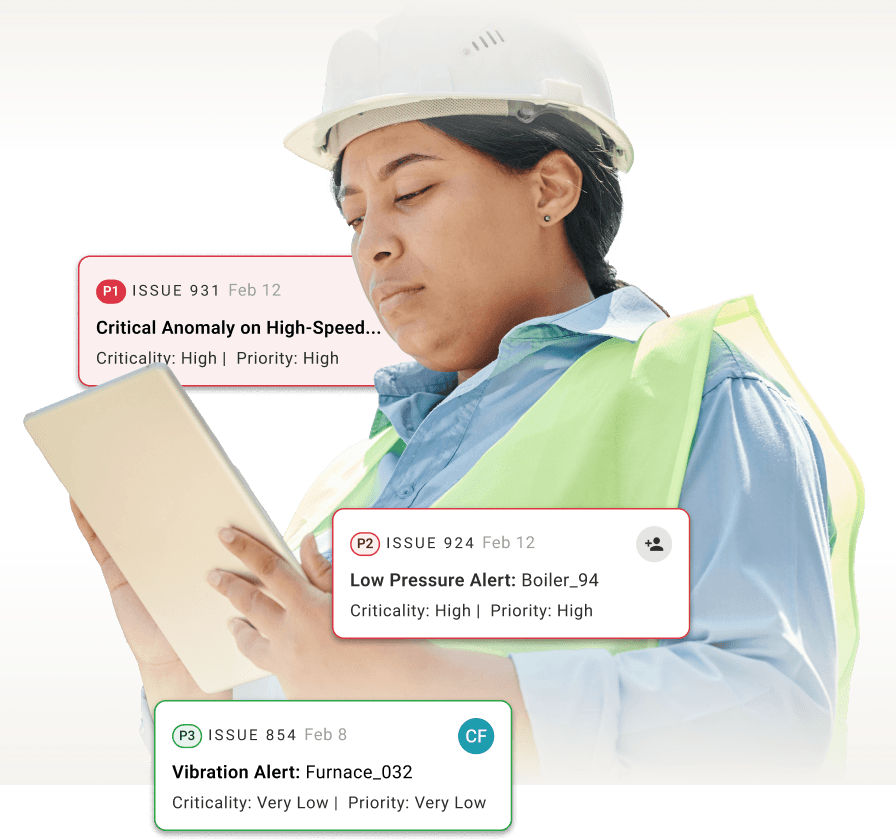

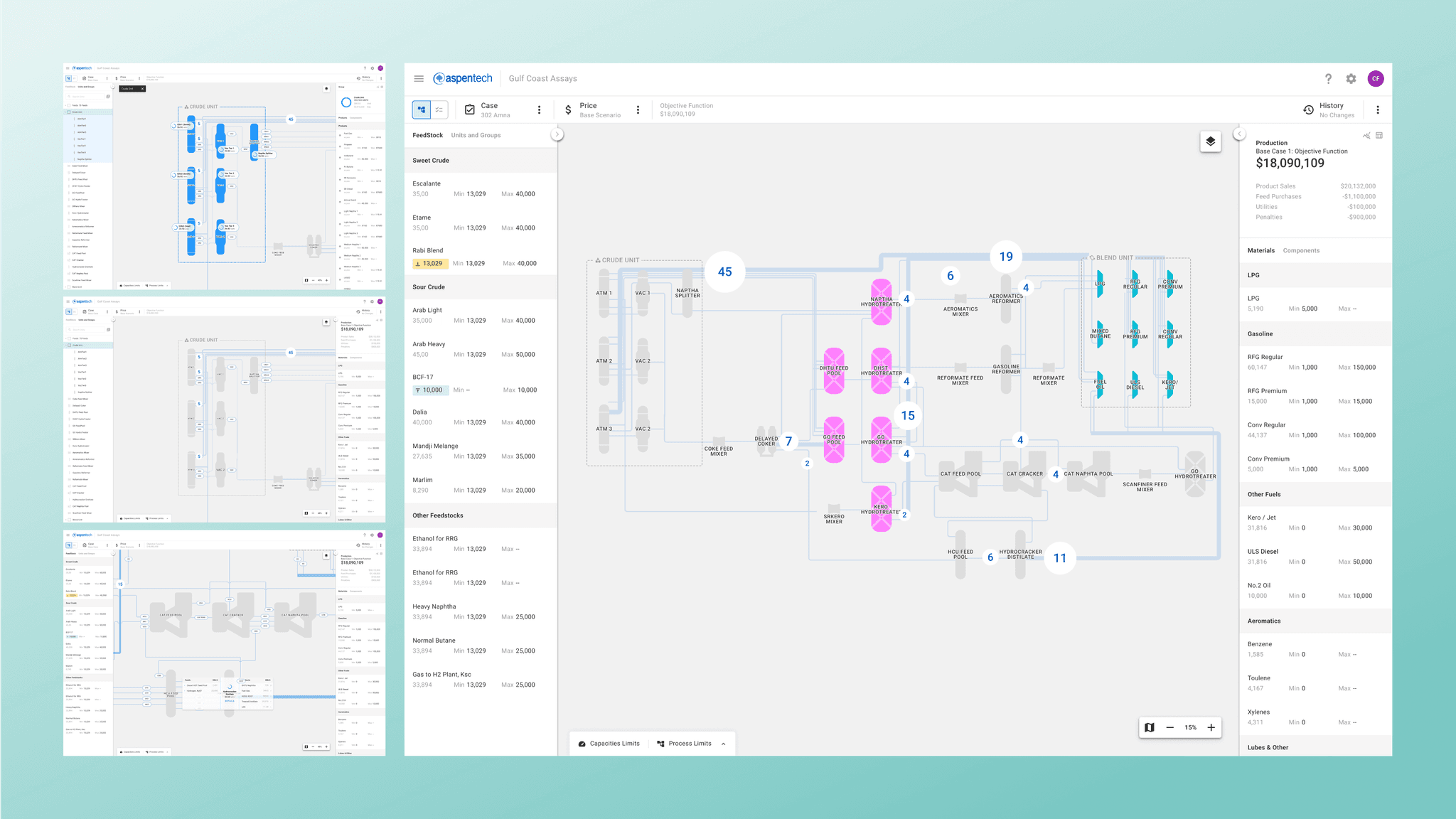

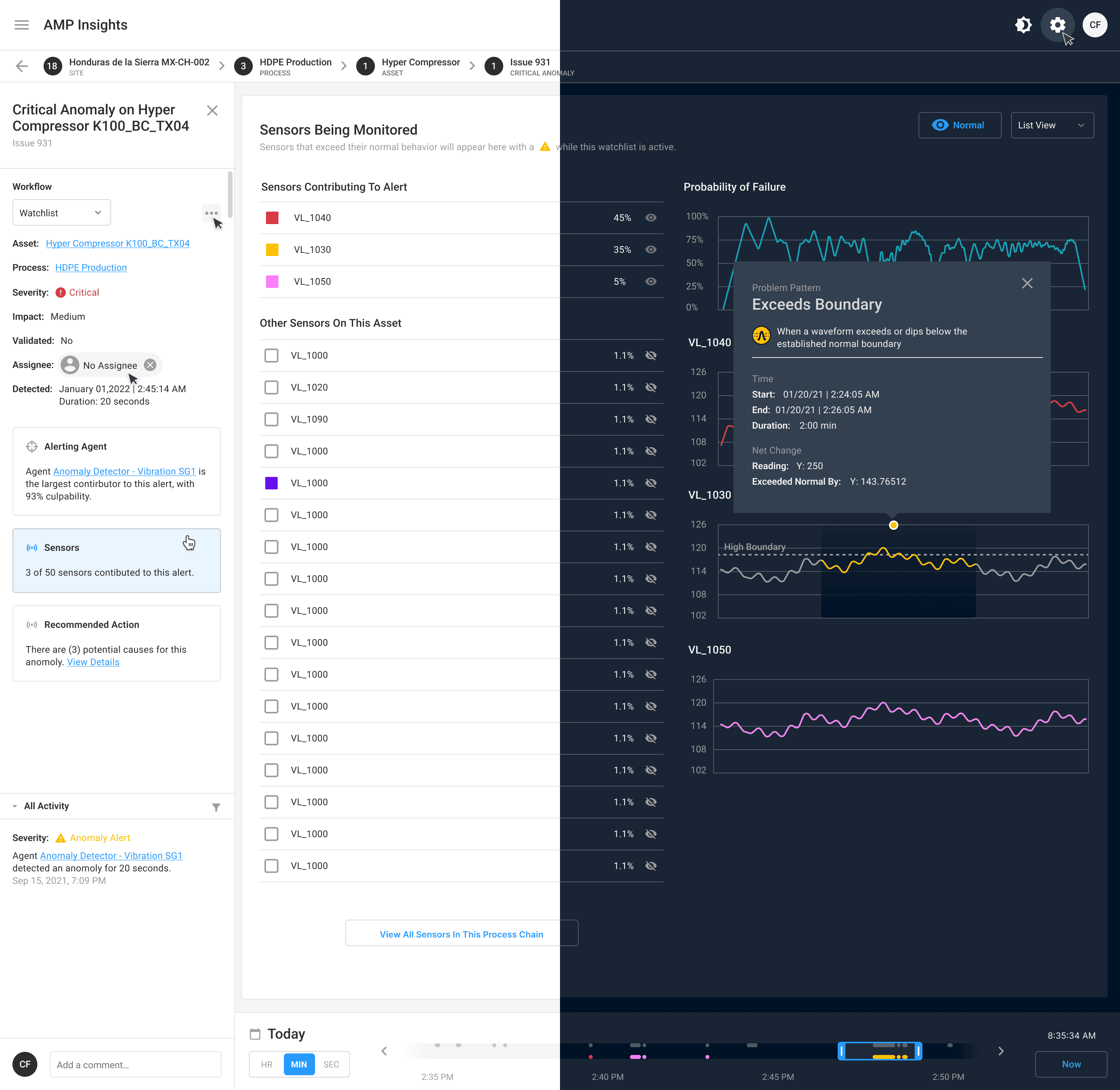

Aspentech envisioned a new offering: an asset management and alert system that decreased the time for front line plant managers and operators to identify a a risk and take the appropriate action. This solution would combine the power of predictive-analytics with a collaborative space that enables AspenTech’s AI to make recommendations based on historical data—ensuring plant managers and operators who lack this historical knowledge have the ability to see potentially catastrophic problems through the noise of daily operations.

With this revolutionary dashboard, AspenTech can provide valuable insights to plant managers and operators through a single source of truth and prioritize alerts (and groups of alerts) that require immediate adjustment in operations or planning for downtime and repair. This feature will help plant administrators more proactively adjust for disruptions in the production schedule, with the added benefit of reducing the time specialized engineers and maintenance personnel spend on diagnosing and making recommendations.

Ethnographic research paired with design improved collaboration

Our approach was rooted in the principles of qualitative ethnography and participatory design, engaging the individuals who directly use and maintain the application. This user-centered design process ensured that the end result was both effective and practical.

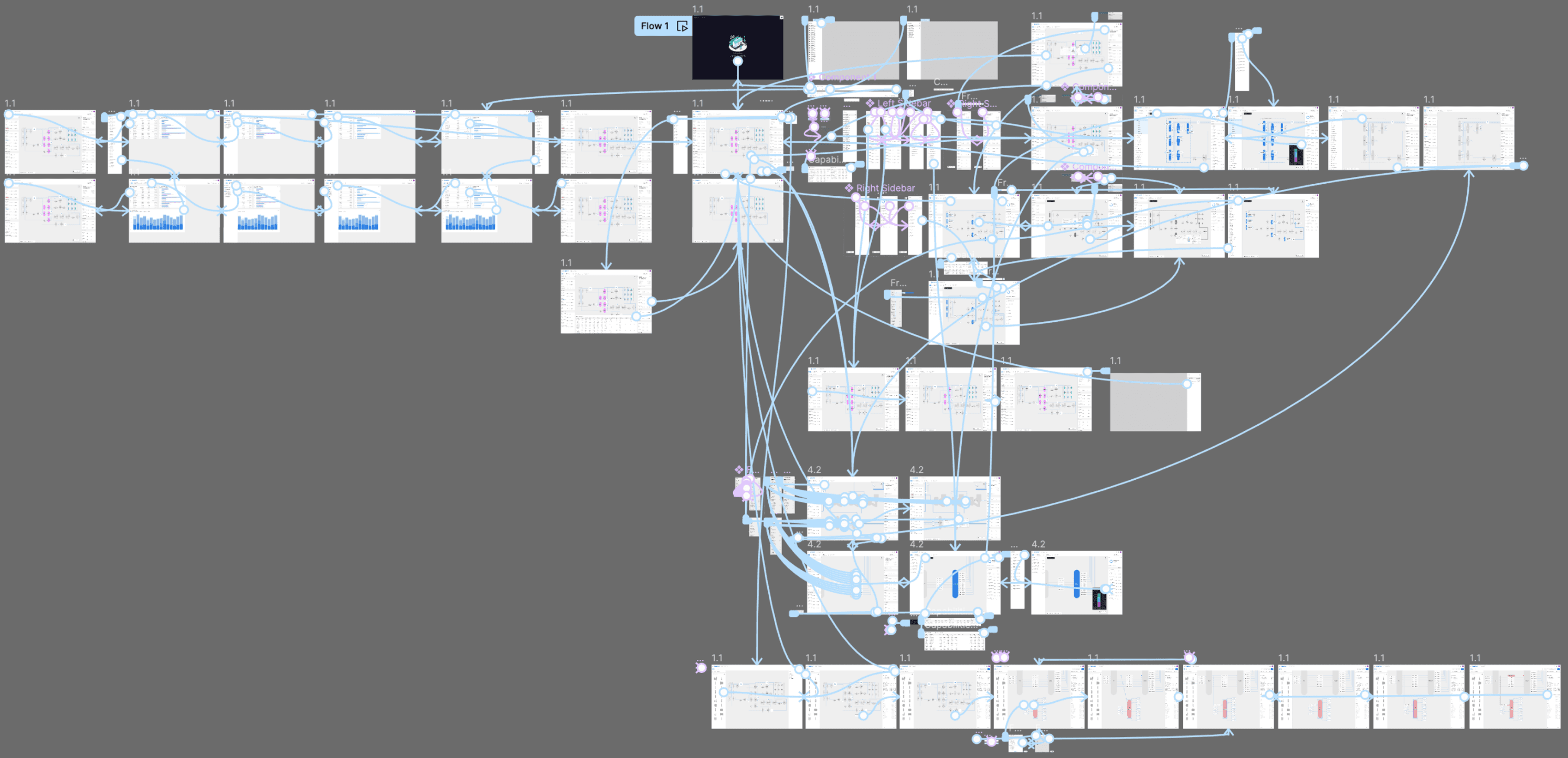

The rapid iteration of low-fidelity prototypes enhanced user testing at each stage, allowing the team to quickly identify and address breakdowns in the collaborative workflows across various manufacturing facilities. This iterative approach encouraged constant feedback and refinement, leading to a well-designed application that improved collaboration and streamlined processes.

We conducted interviews and user testing with alert responders, their managers, and their extended team members.

16

Participants

10

Hour-long discussions

02

Prototype interations

20

Hour-long user testing sessions

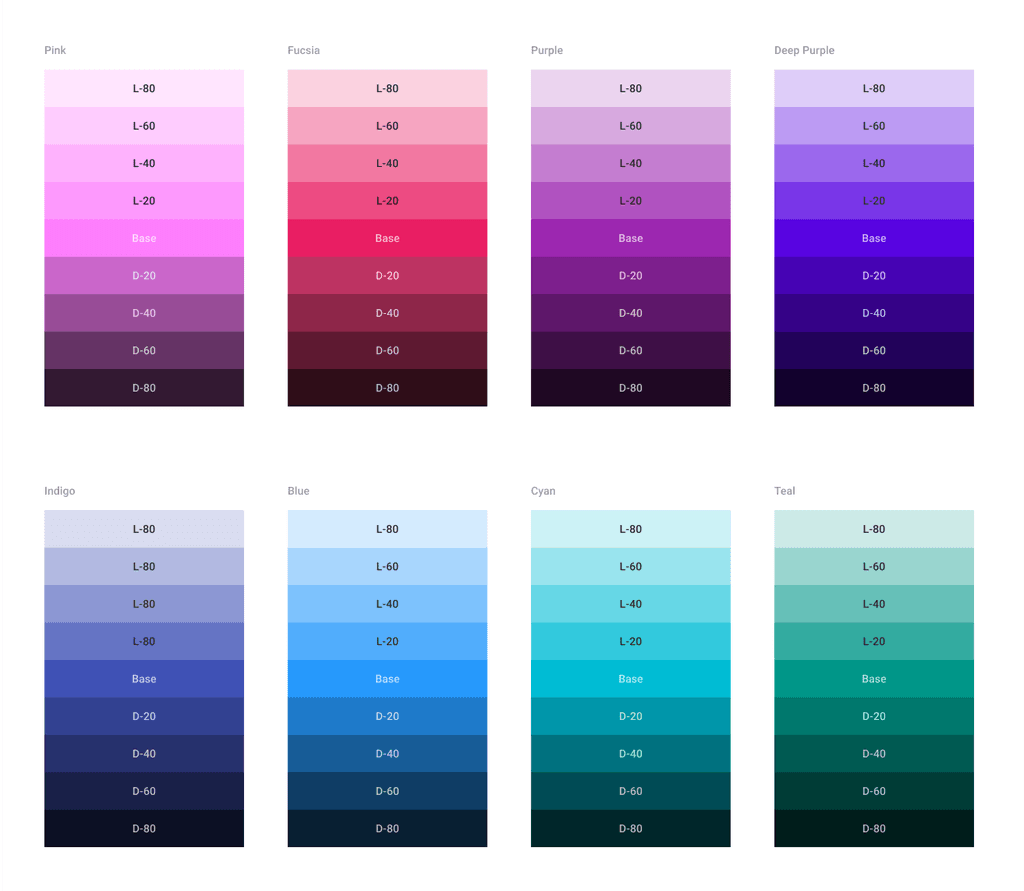

Front-end components for streamlined UI development

We designed a series of components and controls optimized for ease of use, visibility, and information hierarchy display. This UI elements became the base of a comprehensive design language system, one that can easily extend beyond this alerting tool into the rest of the AspenTech product portfolio.

Aspen Mtell® Recognized as Digital Technology of the Year

Aspen Mtell® has received the “Best Digital Technology of the Year” award from the Latin American Refining Technology Conference.

AspenTech was recognized during the 2nd annual “Awards of Excellence” ceremony which celebrates notable achievements throughout the Latin American downstream industry.